Merkmale & Optionen Pi5

- Gehäuse aus Stahl-Mineralguss

- Servoantriebe in allen Achsen, max. 20m/min

- 5-Achsen-Bearbeitung

- 15" Touchscreen-Bedienung, unterstützt durch CIMT HMI-Technologie

- Frässpindel, 50.000 U/min, 4,7 kW Spitzenleistung

- Großer Drehachsen-Schwenkbereich von 35°

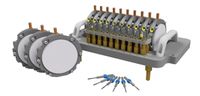

- Eine Kassette für 10 Blanks & 20 Werkzeuge

- 10 Spannringe für Blanks mit einem Durchmesser von 98 mm und einer Dicke von 40 mm

- 2-stufiges Flüssigkühlsystem für Fräswerkzeuge

- Pi-Clean Reinigungs- und Absaugsystem

- Werkzeuglängensensor & 3D-Messtaster

- Fernwartungskamera inklusive Teamviewer QS

- Schwingungsdämpfung der Y-Achse

Materialien in Pi5

Alle gängigen Dentalwerkstoffe können mühelos in der Pi5 zerspant werden.

Blanks für Pi5

Alle gängigen Dentalblanks mit einem Durchmesser von 98 mm können in die Spannringhalter der Maschine eingesetzt werden. Die maximale Höhe der Blanks beträgt 40 mm.

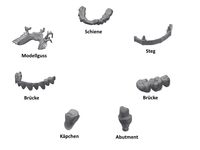

Applikationen erzeugt mit der Pi5

Zu den Standard-Applikationen, die auf der Maschine hergestellt werden können, gehören:

- Käppchen

- Kappen

- Kronen, Brücken

- Inlays, Onlays, Veneers

- Gerüste

- Stege

- Schienen

- Teleskopische Arbeiten

- Abutments, Vorformlinge

Kassettensystem und Spannringe für Pi5

Ein besonderes Merkmal der Maschine ist das modulare Kassettensystem. Sie können bei Bedarf beliebig viele Kassetten extern bestücken, mit bis zu 20 Fräsern und bis zu 10 Blanks. Dies ermöglicht einen optimalen und zeitsparenden Materialwechsel. Ein Spannringhalter kann Material oder Standard-Abutmenthalter aufnehmen.

Das unten beschriebene Scanning-System steigert die Produktivität noch einmal deutlich...

Blank- und Werkzeugabfragefunktion für Pi5

Vor dem Start des Bearbeitungsprozesses prüft die Maschine, ob alle benötigten Werkzeuge vorhanden sind und an welcher Position in der Kassette sie vom Bediener eingelegt wurden. Dazu scannt ein am Werkzeughalter montiertes RFID-Lesegerät alle Positionen in der Kassette. Jedes Werkzeug und Material, das mit RFID codiert ist, kann fehlerfrei identifiziert und zugeordnet werden. Der Scanvorgang kann beliebig oft automatisch oder manuell durchgeführt werden und bietet maximale Sicherheit. Der versehentliche Einsatz eines falschen Werkzeugs ist damit ausgeschlossen. Die Laufleistung in Metern wird nach jedem Werkzeugwechsel in das Werkzeug geschrieben, also direkt im Fräser erfasst.

Pi-Clean Reinigungssystem

Das vollautomatische Reinigungssystem Pi-Clean der Fräsmaschine sorgt für eine schnelle und gründliche Reinigung des Arbeitsraums.

Endschalter und ein Lasermesssystem überwachen die Bewegung.

Späne- und Staubabsaugung für Pi5

Zur sicheren Entsorgung von Spänen und Staub steht eine leistungsstarke Absauganlage mit Filterklasse m nach EN 60335-2-69 zur Verfügung. Die Absauganlage verfügt über zwei von der Maschine gesteuerte Absauganschlüsse. Ein Anschluss sammelt die Späne während der Bearbeitung, der andere ist mit dem Arbeitsraumreinigungssystem Pi-Clean verbunden, das die nach der Reinigung im Arbeitsraum verbliebenen Späne aufsaugt. Die wartungsfreie Absaugturbine, die für viele tausend Betriebsstunden ausgelegt ist, gewährleistet einen 24/7-Betrieb.

3D-Tastsystem für Pi5

Ein taktiler Messtaster zur Kalibrierung der Fräsmaschine und zur Qualitätskontrolle der gefrästen Restaurationen ist ein integraler Bestandteil der Maschine. In der Industrie bereits seit vielen Jahren Standard, hält diese Messtechnik nun auch in der Dentalbranche Einzug. Der 3D-Messtaster erkennt während der Produktion automatisch notwendige Fräsabweichungen, woraufhin die Steuerung der Maschine einen Nachfrässchritt durchführt.

Maßgeschneiderte Benutzeroberfläche

Die Pi5 CNC-Dentalfräsmaschine verfügt über eine maßgeschneiderte Benutzeroberfläche, die auf die spezifischen Bedürfnisse von Zahntechnikern und Klinikern zugeschnitten ist. Diese Schnittstelle bietet eine intuitive und benutzerfreundliche Erfahrung und ermöglicht eine einfache Navigation und Kontrolle über den Fräsprozess. Mit dem Schwerpunkt auf Einfachheit und Effizienz trägt die Schnittstelle dazu bei, den Arbeitsablauf zu optimieren und die Produktivität zu steigern, während gleichzeitig das Fehlerpotenzial minimiert wird.

Dem Zahntechniker steht eine von CIMT und Bosch Rexroth entwickelte Benutzeroberfläche zur Verfügung, die einfach und intuitiv zu bedienen ist. Sie wird auf einem industriellen 15,4-Zoll-Touchscreen mit Sicherheitsglas Abdeckung angezeigt und gewährleistet eine fehlerfreie Bedienung auch in rauen Umgebungen.

Vom Laden der Werkzeuge und Blanks über das Laden des Auftrags bis hin zur Live-Simulation lässt die Benutzeroberfläche keine Wünsche offen. Nach oder während der Fertigstellung der Aufträge kann der Zahntechniker die fertige Arbeit mit der Live-Simulation vergleichen und bei Bedarf eine feinere oder gröbere Strategie in der CAM wählen. Das sorgt für eine noch zeitsparendere Fertigung Ihrer Arbeit.

Eine kontinuierliche Weiterentwicklung ist selbstverständlich.

Technische Details

Nachfolgend finden Sie einen einfachen Aufstellungsplan mit technischen Daten für die Pi5-Fräsmaschine, den Sie als PDF oder als einfaches Bild herunterladen können.

Vernetzt für maximale Verfügbarkeit |

Zusammenarbeit mit Bosch Rexroth Mit ihrer benutzerfreundlichen Oberfläche und ihren leistungsstarken Bearbeitungsfunktionen kann sie schnell und präzise eine Vielzahl von Zahnrestaurationen herstellen. Darüber hinaus ermöglichen die Konnektivitätsfunktion eine nahtlose Integration mit anderen digitalen zahnmedizinischen Arbeitsabläufen und Technologien, was einen rationalisierten und effizienten Produktionsprozess ermöglicht. Die Pi5 wurde in Zusammenarbeit mit der CNC-Systemlösung MTX von Bosch Rexroth als eine CNC-Maschine für die 5-Achsen-Simultanbearbeitung entwickelt, die so klein ist wie ein eigenständiger Kühlschrank und bereit für das Internet der Dinge (IoT), und zwar vollständig in einer virtuellen Umgebung. Es ist die erste Maschine im Dentalmarkt, die komplett mit einem digitalen Zwilling des Rexroth-CNC-Systems MTX entwickelt und getestet wurde. |